What Cause Truck Front Wheel Bearing Failure

Truck Front Wheel Bearing Structure

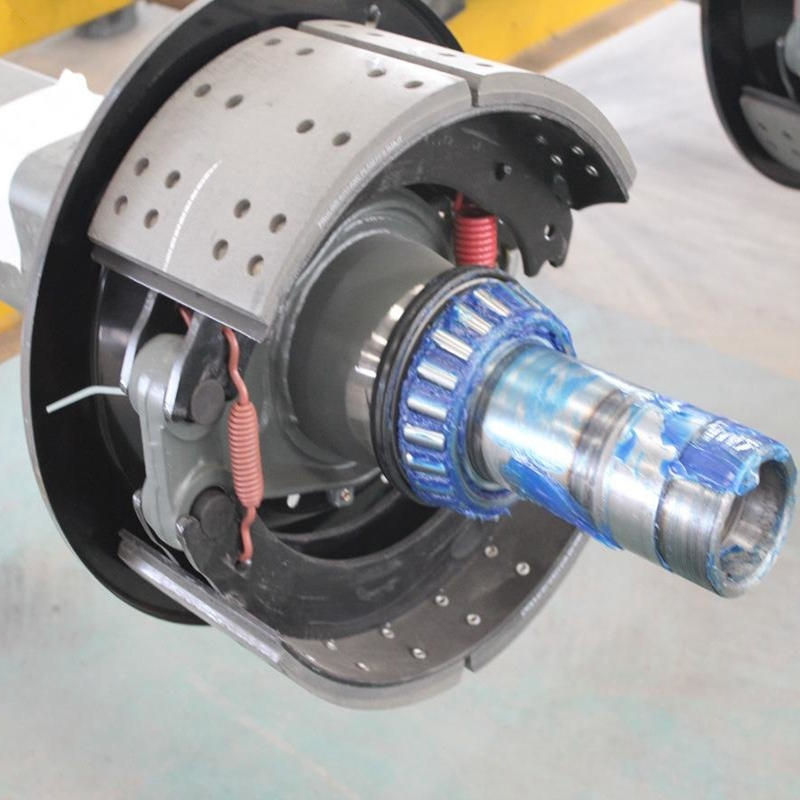

Truck front wheel bearing is rolling bearing. The basic structure of the rolling bearings is as below.

The front wheel assembly of the truck is equipped with inner and outer 2 sets bearings (for examaple, SET403, SET406 3782-3720, SET415).

The bearings are lubricated with grease. According to the performance and design principles, the bearings are taper roller bearings. Taper roller bearing basic structure contains of 4 parts: outer ring, inner ring, rolling element and cage.

The outer ring and the inner ring are assembled with the journal and the bearing seat respectively. Usually the outer ring is fixed and the inner ring rotates with the journal.

The rolling elements run on the raceways of the inner and outer rings.

The cage separates the rolling elements evenly in order to avoid wear increasing by avoiding direct contact between adjacent rolling elements.

Analysis of the Cause of Damage to the Truck Front Wheel Bearings

1. Operation Reasons

①Overload

The loading quality of the truck is designed to be 260 tons. Due to heavy production tasks and limited operator skills, truck overloads frequently occur. This will increase the load-bearing capacity of the truck’s front wheels and the pressure of the front wheel bearings. As a result, the front wheel bearings are easier to broken.

②Lack of operational skills

When the truck is running at high speed, the brake use frequency will increase or the brake will be used more urgently. In this way, the truck’s own weight and load will mostly concentrate on the front axle due to the impact force, and the impact force on the front axle will mainly act on the front wheels. As a consequence, such a large impact force will inevitably aggravate the damage of the bearing, thereby greatly reducing the service life of the bearing.

③Continuous operation

In the open-pit mining area, heavy-duty truck operators use 4 shifts and 3 shifts manufacturing operations, so continuous operations are more frequent. When a shift is over, the truck will be handed over to the next shift operator to work if there is no fault. This will cause the truck to dissipate incompletely, stay in a high temperature state for a long time, and the temperature of the front wheel bearing will also increase. In this way, the lubricating performance of the grease will reduce, thereby aggravating the wear of the front wheel bearings.

2. Bearing Quality Problem

①The quality of the bearing material is not high. In terms of the quality of the bearing material itself, there are cracks, spots and burrs on the bearing surface. These defects are the main causes of bearing damage.

②Improper Grease

Truck production tasks are heavy. Due to the large temperature difference in the working environment, the viscosity of the grease also changes, so that the grease does not have the effect of high temperature and high pressure resistance. The viscosity of the grease will decrease and become diluted for a long time. Therefore, it will cause a large loss of grease, which seriously affects the lubrication efficiency of the bearing and eventually increases the wear of the bearing. As a result, bearing failure will happen.

3. Maintenance Skill Factor

①Improper use of liquid nitrogen

Before installing the bearing, it is necessary to soak the bearing sleeve with liquid nitrogen. The purpose is to make the bearing sleeve cold shrink and easy to install. If the immersion time is short, the bearing cannot be installed correctly. Similarly, if the immersion time is long, the toughness of the bearing sleeve will be reduced. If the toughness is reduce, the service life of the bearing sleeve will be decrease as well, which will seriously affect the use of the bearing.

②Improper Measuring Method of Gap

After fixing the bearing, the gap between the bearing and the pressure plate should be measured. But sometimes in the process of measurement, personnel neglect the accuracy of the vernier caliper, and the vernier caliper does not return to zero, which increases the measured gap. This will affect the service life of the bearing and the bearing will be damaged

③Inappropriate Pads Adjustment

Sometimes maintenance personnel do not add adjustment pads according to the specified measurement values, but add them according to their own experience. This will eventually lead to more or less adjustment pads, which affects the use of the bearing

Contact Us:

If you have any questions about What Cause Truck Front Wheel Bearing Failure, pls contact us. We will give you answer within 12 hours!