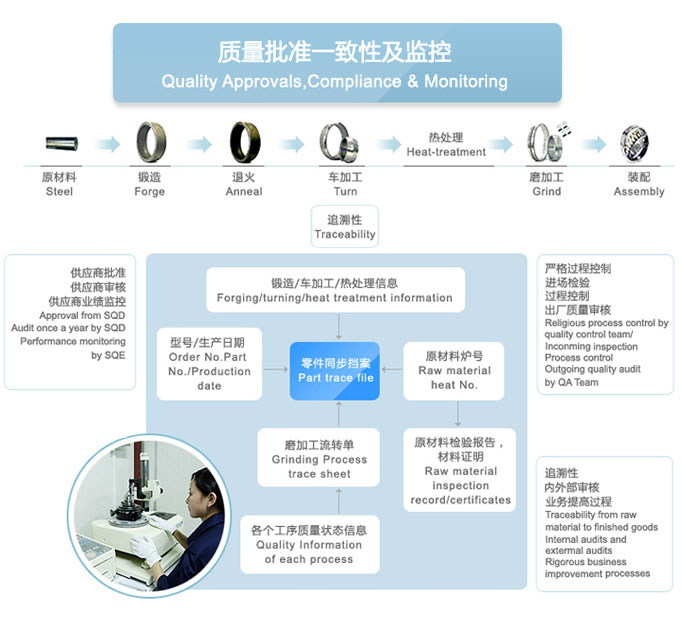

Through the pre quality planning, we have quality management system as the guarantee from the design and development of the products, the purchase of raw materials, the storage and production, to the inspection, packaging and transportation of the finished products.

At the same time, we have our own physical and chemical laboratory, each batch of incoming materials are tested and analyzed to ensure that each batch is of high quality raw materials.

In the process, we imported high precision measuring and testing equipment, and established metrology testing room to ensure the accuracy of process measurement.

Automatic controls specific to our products have been developed and implemented in the manufacturing process:

Our process includes measurement by means of eddy currents, to determine microcracks and hardness in the rollers.

Groove Ball Bearing Quality Control – Trusted Inspection

Precision You Can Depend On

At Groove Ball Bearing, quality is the foundation of everything we do. Our quality control processes are tailored to meet international requirements, with special attention given to all bearings manufactured in our facility. Quality assurance mechanisms begin with raw material inspection and culminate with final assembly checks.

Comprehensive Testing at Every Stage

Dependable performance of bearings is non-negotiable for you, and for us. In addition to thorough testing at the end of the manufacturing cycle, each product is subjected to rigorous evaluation during various phases of production. Our in-house quality control system includes:

- Inspection of Materials: Test all steel received in the form of several batches against bearing-grade standards using bearing-grade standards-compliant chemical and structural analysis.

- Accuracy of Dimensions Assessment: Confirming components against intended value by use of CNC coordinate measuring machines and micrometers to accurate measure components against specified tolerances.

- Finish (Surface and Precise Shaping) Evaluation: Carrying out Rockwell hardness tests and surface roughness testing to matrix of wear resistance.

- Noise and Vibration Evaluation: Confirm absence of vibration and sound during operation for automotive and motor applications, especially.

- Test of rotational power against load applied: Conditioning the bearings dynamically to simulate working conditions and validating operated with conditions against ability to carry load without qualitative change in performance.