ZKLN Bearings

ZKLN Bearings Introductions:

ZKLN bearings belong to axial angular contact ball bearings which are widely used for screw drive

Bearings of ZKLN and ZKLF series are double row axial angular contact ball bearings.

As a result, ZKLN bearing can support radial forces as well as axial forces in both directions.

Moreover, the bearings are available with and without fixing holes in the outer ring. Bearings with holes are screw mounted directly on the adjacent construction.

Normally speaking, ZKLN bearing working temperature is -30°C to 120°C

Common bearing suffixes are as below,

2RS: contact lip seals on both sides

2Z: minimal gap seals on both sides

TVP: plastic cage

2AP: Axial matched bearings (only for ZKLF / ZKLN)

PE: increased tolerances (only for ZKLF / ZKLN)

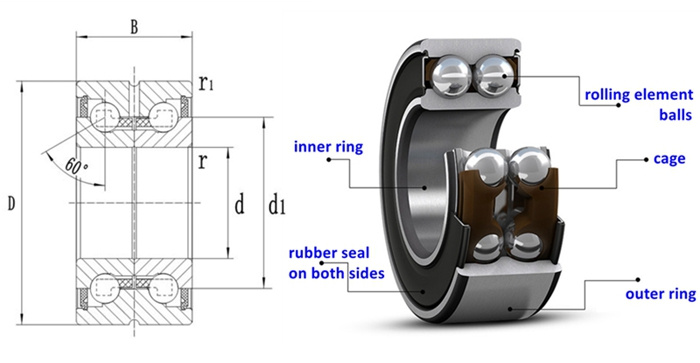

Structure:

ZKLN Series Bearings Size Chart:

| Model Number | d (mm) | D(mm) | B(mm) | Mass (g) |

| ZKLN0619.2RS | 6 | 19 | 12 | 18 |

| ZKLN0619.2Z | 6 | 19 | 12 | 18 |

| ZKLN0832.2RS | 8 | 32 | 20 | 90 |

| ZKLN0832.2Z | 8 | 32 | 20 | 90 |

| ZKLN1034.2RS | 12 | 42 | 25 | 98 |

| ZKLN1034.2Z | 12 | 42 | 25 | 98 |

| ZKLN1242.2RS | 12 | 42 | 25 | 200 |

| ZKLN1242.2Z | 12 | 42 | 25 | 200 |

| ZKLN1545.2RS | 15 | 45 | 25 | 210 |

| ZKLN1545.2Z | 15 | 45 | 25 | 210 |

| ZKLN1747.2RS | 17 | 47 | 25 | 220 |

| ZKLN1747.2Z | 17 | 47 | 25 | 220 |

| ZKLN2052.2RS | 20 | 52 | 28 | 310 |

| ZKLN2052.2Z | 20 | 52 | 28 | 310 |

| ZKLN2557.2RS | 25 | 57 | 28 | 340 |

| ZKLN2557.2Z | 25 | 57 | 28 | 340 |

| ZKLN3062.2RS | 30 | 62 | 28 | 390 |

| ZKLN3062.2Z | 30 | 62 | 28 | 390 |

| ZKLN3572.2RS | 35 | 72 | 34 | 510 |

| ZKLN3572.2Z | 35 | 72 | 34 | 510 |

| ZKLN4075.2RS | 40 | 75 | 34 | 610 |

| ZKLN4075.2Z | 40 | 75 | 34 | 610 |

| ZKLN 5090.2RS | 50 | 90 | 34 | 880 |

| ZKLN 5090.2Z | 50 | 90 | 34 | 880 |

Bearing Features:

1. ZKLN are mainly used for machine tool screw with good running support performance

2. Low noise and energy saving, high wear resistance and long life

3. High precision with high guiding accuracy

4. The bearings are available with and without fixing holes. Bearings with holes are screw mounted directly on the adjacent construction.

This solution is particularly economical since there is then no need for the locating bore that would otherwise be required or for the bearing cover with the associated matching work.