What Does P4S Mean in Bearings

What Does P4S Mean in Bearings – Introduction:

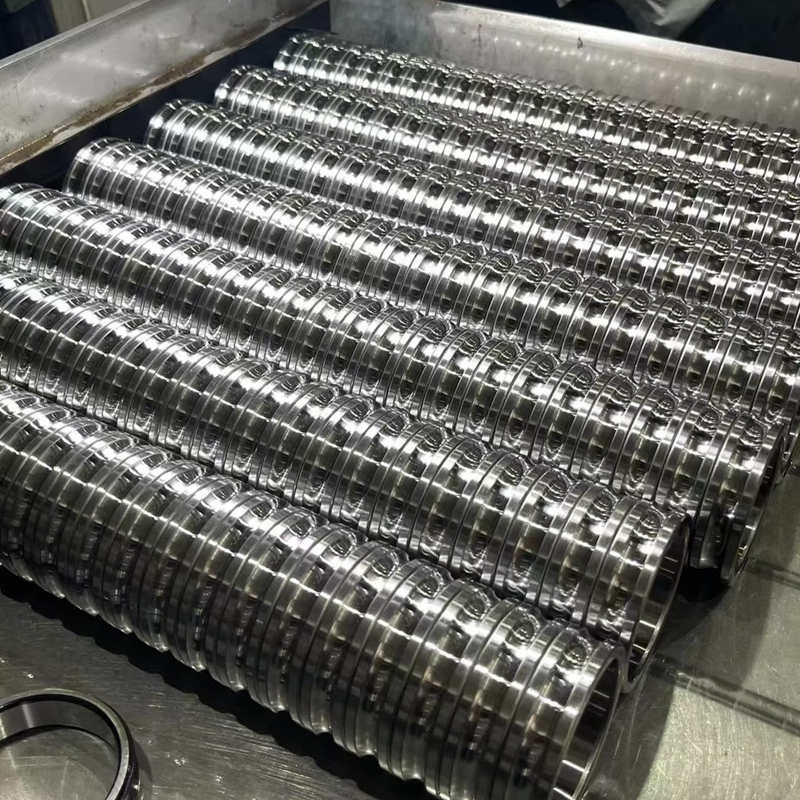

What does P4S mean in bearings? Bearings are essential to the operation of machinery, impacting not only performance but also durability and reliability. When it comes to high-precision applications, bearing accuracy becomes even more important. Manufacturers use specific classification codes to indicate different tolerance and precision levels, and “P4S” is one such designation that often appears. But what exactly does P4S represent, and why does it matter?

Understanding Bearing Precision Grades:

Bearings are manufactured to different precision grades, which specify their dimensional accuracy and running tolerances. These grades are set by international standards such as ISO and DIN, and are indicated by codes like P0, P6, P5, P4, P2, and sometimes with additional letters.

Applications that demand exceptional rotational accuracy, high speeds, and minimal vibration—such as machine tools, robotics, and aerospace equipment—require bearings with higher precision grades. In these advanced fields, even the slightest deviation in bearing performance can lead to reduced efficiency, increased wear, or costly downtime. As a result, selecting bearings with superior precision is essential to ensure optimal operation, longevity, and reliability in these demanding environments.

What Does “P4S” Mean?

Schaeffler Group brands like FAG and INA primarily use the precision grade code “P4S.” Here’s a breakdown:

- P4: This refers to the ISO or DIN tolerance class, indicating a very high level of precision (ISO 492 Class 4, DIN 620 Class 4).

- S: The “S” signifies “Super” or “Special,” and manufacturers use it to indicate even tighter tolerances than standard P4. They specifically design these bearings for spindle applications that demand high speed and exceptional precision.

Manufacturers design P4S bearings with even stricter tolerances than standard P4 bearings, which allows these bearings to deliver superior precision and reliability. This heightened accuracy helps P4S bearings perform exceptionally well in demanding environments where consistent operation and minimal deviation are essential. For applications that require maximum speed, stability, and durability, engineers often choose P4S bearings for their outstanding performance.

Comparison: P4S vs Other Precision Grades:

| Grade | Tolerance Level | Typical Applications |

|---|---|---|

| P0 | Standard | General machinery |

| P6 | Higher | Automotive, industrial equipment |

| P5 | High | Precision machinery |

| P4 | Very High | Machine tool spindles |

| P4S | Super High | CNC spindles, high-speed tools |

| P2 | Ultra High | Aerospace, metrology |

P4S offers better rotational accuracy, lower runout, and higher speed capabilities compared to standard P4.

Applications of P4S Bearings:

P4S bearings are typically used in:

- CNC machine tool spindles

- Precision grinding machines

- High-speed milling machines

- Robotics and automation

- Measurement and inspection equipment

These applications demand minimal vibration, high rotational accuracy, and reliability at high speeds.

Benefits of Using P4S Bearings:

- Achieve exceptional accuracy and consistent reliability, even in the most demanding applications

- Minimize vibration and noise levels, contributing to smoother and quieter machine operation

- Extend service life, especially under high-speed and heavy-load conditions

- Enhance overall machine performance and stability in challenging environments

- Deliver superior surface finishes in machining processes, resulting in higher-quality end products

How to Identify P4S Bearings?

P4S bearings are usually marked on the bearing itself or mentioned in the product documentation. Look for codes such as “P4S” in the bearing designation, especially from manufacturers like FAG or INA.

Example:

FAG B7010-E-T-P4S-UL

Here, “P4S” indicates the precision grade.

Conclusion:

Understanding what “P4S” means in bearings helps you select the right component for high-precision, high-speed applications. If your machinery demands superior accuracy and reliability, opting for P4S-grade bearings can make a significant difference in performance and longevity.

Are you looking for P4S bearings for your next project? Contact us for expert advice and competitive pricing!