Electrical Motor Bearings

Electrical Motor Bearings Introduction:

Electrical Motor Bearings- For rotating electrical motors (what are electrical motors?), bearings are very important components. Their performance and life directly affect the performance and life of the motor.

Improving the performance and quality of bearings is an important aspect to ensure the stable and reliable operation of the motor.

Motor Bearings Classification:

The rolling bearings commonly used in motors are deep groove ball bearings(for example 6203-2Z/C3, 6005 ), angular contact ball bearings, cylindrical roller bearings, and spherical roller bearings.

1. Deep groove ball bearings are generally used for bearings at both ends of small motors; angular contact ball bearings are also used in some parts.

2. Medium-sized motors generally use roller bearings at the load end and ball bearings at the non-load end.

3. Large motors generally use spherical roller bearings.

Performance Requirements:

The main use requirements of motor bearings are no abnormal sound, low vibration, low noise, low temperature rise and long life.

No abnormal sound mainly requires that there is no abnormal sound caused by sliding friction during the operation of the bearing.

After the machine is installed, run the machine without load, and distinguish the abnormal sound other than electromagnetic sound and fan sound by listening.

Vibration and noise are the most important requirements for bearings. After installation, the vibration value of the whole machine must meet the factory requirements.

Lubrication:

Motor bearings are generally lubricated with grease and oil, and a few of them are self-lubricated. In most general purpose motors, sealed grease lubricated bearings are widely used.

| Item | Grease Lubrication | Oil Lubrication |

| Sealing System | sample | complicated, need to pay attention to the maintenance |

| Lubrication Performance | good | good |

| Rotating Speed | low speed | medium speed and high speed |

| Torque | large | small |

| Lubricant Replacement | complicated | sample |

| Lubricant Life | short | long |

| Cooling Effect | no | good (requires loop) |

| Filtration of Impurities | difficult | easy |

| Leakage of Lubricant | less oil leakage and less pollution | not suitable for places where oil leakage is not allowed |

Clearance:

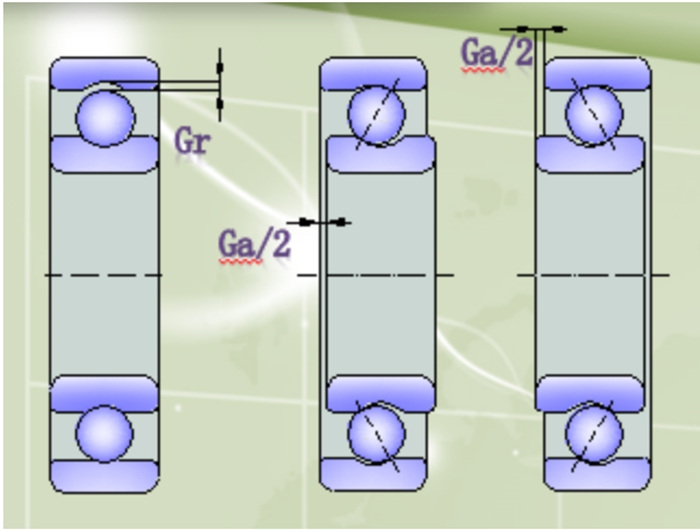

Usually, we select the same clearance bearings at both ends of the motor. Theoretically, the bearing operates best in a state of close to zero clearance under working conditions. Considering the tolerance factors of assembled parts, it is almost impossible to achieve this requirement. If an axially acting spring element is used to adjust the bearing, play-free operation can also be achieved, but the formation of the bearing contact angle will reduce the load capacity of the bearing. Bearing clearance generally includes radial and axial directions (we only focus on radial clearance for cylindrical roller bearing).

Gr—-Radial clearance

Ga—-Axial clearance

Contact Us:

If you have any questions of Electrical Motor Bearings, pls feel free to contact us!