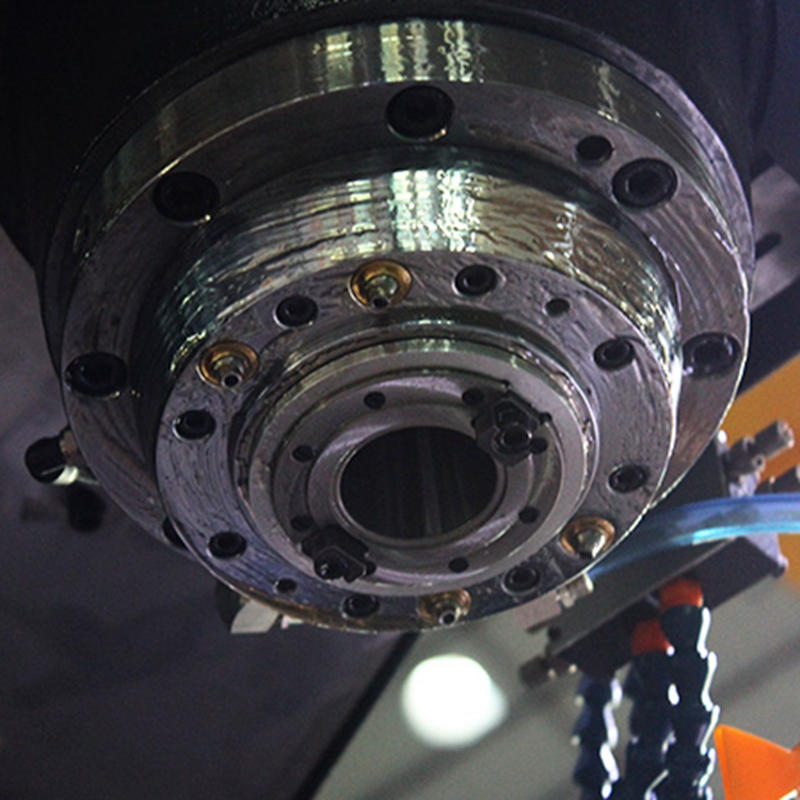

How to Clean Lathe Spindle Bearings

How to Clean Lathe Spindle Bearings

Clean lathe spindle bearings (for example B7013.C.T.P4S.UL) regularly is very important.

As a key component of the machining center, the lathe spindle will directly affect the speed, rigidity, temperature rise and noise of the machining center.

In order to maintain excellent machining capabilities of the machine tool, users should clean lathe spindle bearings regularly.

The cleaning of the lathe spindle bearing will also affect its working condition and service life.

Many failures of CNC machining centers are caused by improper cleaning of bearings, so users should pay adequate attention to the cleaning of spindle bearings.

The main points of cleaning lathe spindle bearings are as follows.

1. Keep your hands clean and dry

When operator take precision bearing out of the package, the operator should keep hands clean and dry, because sweat on the hands can cause rust.

Operators can wear gloves if necessary.

2. Ensure good lubrication effect

The removed precision bearing should be greased and oiled immediately.

After the greased precision bearing is taken out, it shall be installed without pollution immediately, without grease and oil treatment.

3. Seal the packaging

Precision bearings can only be removed from the original packaging for cleaning before assembly. After taking out several sets of precision bearing packages sealed with volatile corrosion inhibitors, the packages should be sealed immediately, because the protective gas of VIC paper can only be kept in the sealed package.

4. Clean properly

Grease precision bearings cannot be cleaned before assembly.

While ungreasing precision bearings must be cleaned before assembly. After cleaning, they should be dried and immediately applied with anti-rust oil or grease in order to avoid corrosion.

Contact Us:

If you have any questions of Clean Lathe Spindle Bearings, pls feel free to contact us. We will give you reply within 12 hours!