Bearing Material

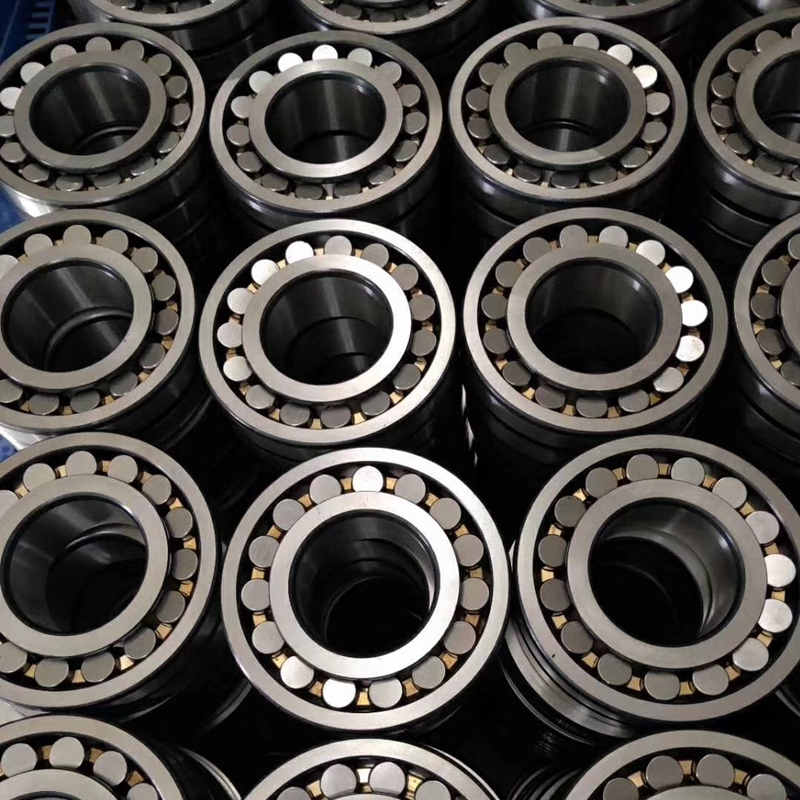

Bearing Material Introduction:

Bearing material is chosen on the basis of dimensional stability, resistance to corrosion and resistance to damage or wear occurring when accidentally applied loads are sufficiently high.

Normally bearing material include the material of bearing rings, rolling elements, cage, sealings.

Rings and Rolling Element Material:

Rolling bearings need to maintain high-precision rotation while repeatedly bearing a large force on the contact surface of the ring and the rolling element.

The load will eventually fracture the surface and cause the bearing to fail.

In order to delay the occurrence of material fatigue, bearing rings and rolling element materials should have the following characteristics.

1. High hardness

2. Strong anti-rolling fatigue performance

3. Wear resistance

4. Good dimensional stability

5. Good mechanical strength

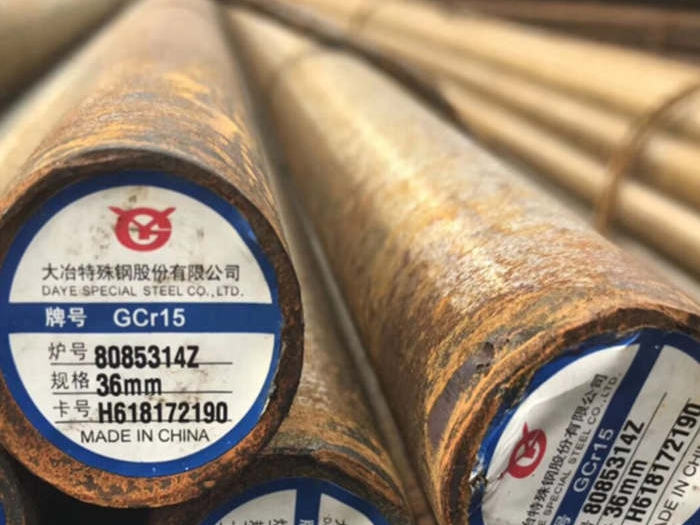

Today, carbon chromium steel (GCR15) is the best choice for rolling bearings. As a result, it has a wide range of applications.

Due to the continuous requirements for bearing life continuity, the carbon chromium steel of ball bearings provides the greatest balance between manufacturing and application performance.

This kind of steel usually occurs during the heat treatment of martensite or bainite, and the hardness ranges between 58 to 65 HRC.

Vacuum degassing, chromium bearing steel GCr15 is a material standard for precision ferrules and rolling elements.

This material has unified specifications AISI52100 (USA), DIN100Cr6 (Germany), JISSUJ2 (Japan).

Gcr15

Chemical Composition of GCR15:

| Steel Code | Chemical Composition% | ||||||||

| GCr 15 SAE52100 JISSUJ2 DIN 100 Gr6 |

carbon | silicon | manganese | phosphorus | sulfur | chromium | molybdenum | copper | nickel |

| 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | ≤0.02 | ≤0.015 | 1.4-1.6 | 0-0.08 | 0.06-0.02 | ≤0.2 | |

Cage Material:

Bearing cage material must have good wear resistance, dimensional stability, good mechanical strength, and the characteristics of perfect adaptation to the operation of the bearing.

Therefore, we should choose the correct cage material according to the operating environment.

Common bearing cage materials include stampled steel, brass, nylon.

Stamped Steel Cage:

These lightweight cages have high strength, and the surface treatment can effectively reduce friction and wear.

Therefore stampled steel cages are widely used in all kinds of bearings. For example, 22211EXN, 6306, etc.

The following table shows the material composition of cold-rolled sheet steel.

| Steel Code | Chemical Composition % | ||||||

| JISG 3141 SPCC | carbon | manganese | phosphorus | sulfur | |||

| < 0.12 | < 0.5 | < 0.04 | < 0.045 | ||||

Brass Cage:

Small and medium-sized bearings use cut brass cages, for example 611GSS bearing.

But brass cages are not suitable for compressors that use ammonia cooling, because ammonia causes the brass to crack seasonally, so steel cages should be used instead.

| Standard | Code | Chemical Composition % | ||||||||

| copper | zinc | manganese | iron | aluminum | tin | nickel | Impurity | |||

| aluminum | silicon | |||||||||

| JIS H 5120 |

CAC301 (HBsC 1) |

55.0 – 60.0 | 33.0 – 42.0 | 0.1 – 1.5 | 0.5 – 1.5 | 0.5 -1.5 | < 1.0 | < 1.0 | < 0.4 | < 1.0 |

| JIS H 3250 |

C 6782 | 56.0 – 60.5 | 0.1 – 1.5 | 0.49 -1.5 | 0.5 -1.5 | – | – | < 0.5 | – | |

Nylon Cage:

Nylon cage is also called plastic cage.

According to the types and uses of bearings, nylon cages are used more and more widely, but they are not suitable for environments above 120°C or below -40°C.

Most cast-molded cages use nylon PA66, which may be reinforced with or without glass fiber, and is characterized by a good combination of strength and elasticity.

Mechanical properties such as the strength and elasticity of nylon depend on temperature and permanent changes under operating conditions.

The most important factors that play a role in this aging operation are temperature, time and the medium in contact (lubricant).

Cage life decreases with the increase in temperature and the aggressiveness of the lubricant.

Therefore, whether the nylon cage is suitable for a specific purpose depends on the operating conditions and life requirements.

nylon cage

Nylon Cage Advantages:

1. Lightweight

The light weight makes the bearing more flexible, and it is used in electrical appliances or other energy-consuming products, which plays an important role in energy saving.

2. Little vibration

Low vibration, low heat generation, strong carrying capacity, which can increase the limit speed and service life of the bearing.

3. Low noise

It has low noise and is the first choice for silent bearings, especially for electrical products with high noise requirements.

Sealing Ring Material:

The sealing ring mainly uses nitrile rubber as the material.

At the same time, for high-temperature environments, fluorine rubber and silicone rubber are also widely used.

| Type | ASTM D1418

|

Tempearture | Hardness (Shore A) |

Features | Limit |

| Nitrile Rubber | NBR | (-40~250F) | 40~90 | Low compression characteristics, high ductility, High corrosion resistance, Superior oil resistance |

Not suitable for high temperature conditions, and avoid direct sunlight and chemical erosion |

| Silicone Rubber | MQ/PMQ/VMQ/PVMP | (-94~400F) | 25~80 | 25~80Resistance to high temperature and dryness, Resistance to sun and ozone aging |

Poor surface wear and crack resistance, Relatively high abrasion resistance |

| Hydrogenation (Nitrile Rubber) |

HNBR/NEM | (-30~330F) | 50~90 | Heat resistance, high ductility, chemical resistance | Not suitable for ultra-low temperature conditions, Avoid direct sunlight and chemical erosion |

| Fluororubber | FKM/FPM | (-20~400F) | 50~95 | High temperature resistance, Significant chemical and corrosion resistance, Corrosion resistance to petroleum products |

Not suitable for low temperature working environment |

| Polypropylene Rubber | ACM Rubber | (0~350F) | 40~90 | It has strong resistance to hot oil, sunlight and ozone erosion and also has strong crack resistance | Poor waterproof performance, Not suitable for ultra-low temperature working conditions |

Contact Us:

If you have any questions about Bearing Material, please feel free to contact us. We will give you reply within 12 hours !