How to Mount a Deep-Groove Ball Bearing?

How to Mount a Deep Groove Ball Bearing Introduction:

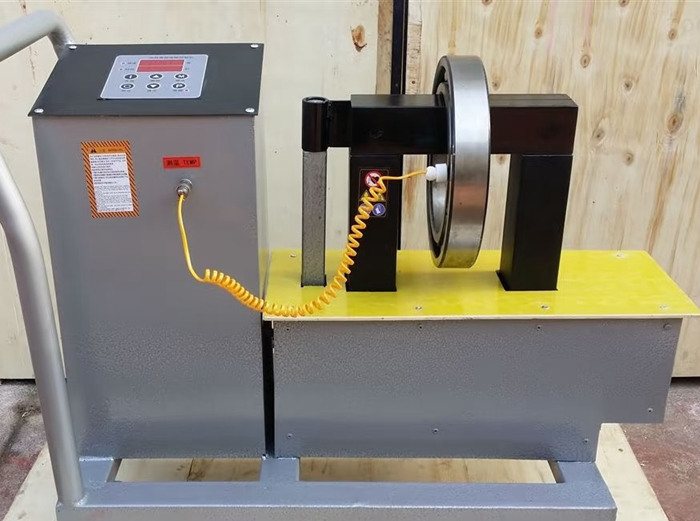

How to mount a deep groove ball bearing may confuse many users. Deep groove ball bearings are among the most commonly used bearings in machinery, prized for their versatility, high-speed capabilities, and durability. However, improper installation can significantly reduce their lifespan and performance. In this guide, we share practical tips to ensure a smooth and safe installation process, helping you get the most out of your bearings.