Stainless Steel Deep Groove Ball Bearings

Stainless Steel Deep Groove Ball Bearings Introduction:

Stainless steel deep groove ball bearings is a common type of bearings.

AISI SUS440 and SUS304 are two common materials for stainless steel deep groove ball bearings.

Difference Between Material SUS440 and SUS304:

SUS440 hardness can reach 58 after vacuum quenching decarburization treatment, suitable for use in weak acid-base and high-load environments.

Because of its high carbon content and magnetism, its corrosion resistance is not as good as SUS304.

To sum up, bearings of SUS440 can reach 1500RPM, hardness is 52-58HRC.

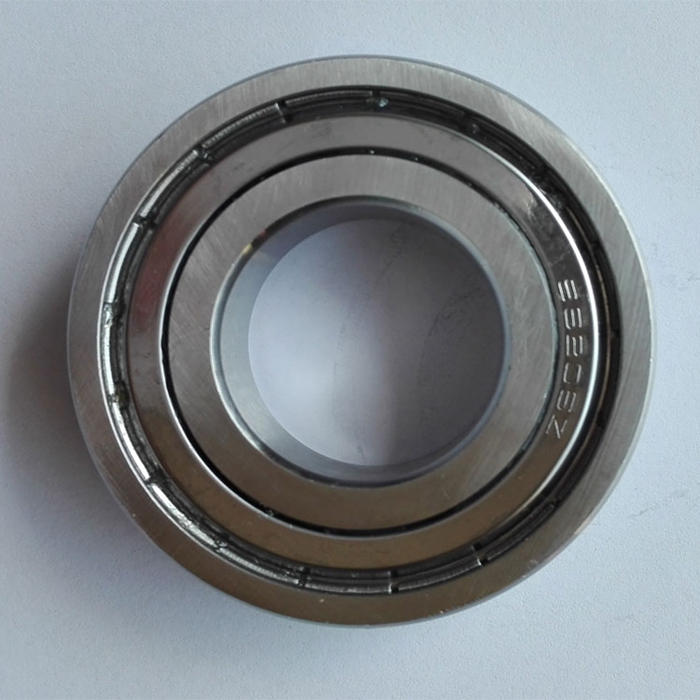

SUS440 stainless steel bearing photo as below:

SUS304 material contains large nickel content and low carbon content, therefore SUS 304 material is soft and has a hardness of about 25.

SUS304 material bearings are not suitable for high-load rotation and are suitable for use in strong acid and alkali environments.

To sum up, bearings of SUS304 is soft and non-magnetic, with Strong acid and alkali resistance and low revolving seed and low precision.

SUS304 stainless steel bearing photo as below:

Stainless Steel Deep Groove Ball Bearing Structure:

Stainless Steel Deep Groove Ball Bearings Size Chart:

| Model | Boundary Size(mm) | |||

| ZZ(RS) | ||||

| ZZ(2RS) | d | D | B | r(min) |

| SS684 | 4 | 9 | 2.5 | 0.1 |

| SS694 | 11 | 4 | 0.15 | |

| SS604 | 12 | 4 | 0.2 | |

| SS624 | 13 | 5 | 0.2 | |

| SS634 | 16 | 5 | 0.3 | |

| SS685 | 5 | 11 | 3 | 0.15 |

| SS695 | 13 | 4 | 0.2 | |

| SS605 | 14 | 5 | 0.2 | |

| SS625 | 16 | 5 | 0.3 | |

| SS635 | 19 | 6 | 0.3 | |

| SS686 | 6 | 13 | 3.5 | 0.15 |

| SS696 | 15 | 5 | 0.2 | |

| SS606 | 17 | 6 | 0.3 | |

| SS626 | 19 | 6 | 0.3 | |

| SS636 | 22 | 7 | 0.3 | |

| SS687 | 7 | 14 | 3.5 | 0.15 |

| SS697 | 17 | 5 | 0.3 | |

| SS607 | 19 | 6 | 0.3 | |

| SS627 | 22 | 7 | 0.3 | |

| SS637 | 26 | 9 | 0.3 | |

| SS688 | 8 | 16 | 4 | 0.2 |

| SS698 | 19 | 6 | 0.3 | |

| SS608 | 22 | 7 | 0.3 | |

| SS628 | 24 | 8 | 0.3 | |

| SS638 | 28 | 9 | 0.3 | |

| SS689 | 9 | 17 | 4 | 0.2 |

| SS699 | 20 | 6 | 0.3 | |

| SS609 | 24 | 7 | 0.3 | |

| SS629 | 26 | 8 | 0.3 | |

| SS639 | 30 | 10 | 0.6 | |

| SS6800 | 10 | 19 | 5 | 0.3 |

| SS6900 | 22 | 6 | 0.3 | |

| SS6000 | 26 | 8 | 0.3 | |

| SS6200 | 30 | 9 | 0.6 | |

| SS6300 | 35 | 11 | 0.6 | |

| SS6801 | 12 | 21 | 5 | 0.3 |

| SS6901 | 24 | 6 | 0.3 | |

| SS16001 | 12 | 28 | 7 | 0.3 |

| SS6001 | 28 | 8 | 0.3 | |

| SS6201 | 32 | 10 | 0.6 | |

| SS6301 | 37 | 12 | 1 | |

| SS6802 | 15 | 24 | 5 | 0.3 |

| SS6902 | 28 | 7 | 0.3 | |

| SS16002 | 32 | 8 | 0.3 | |

| SS6002 | 32 | 9 | 0.3 | |

| SS6202 | 35 | 11 | 0.6 | |

| SS6302 | 42 | 13 | 1 | |

| SS6803 | 17 | 26 | 5 | 0.3 |

| SS6903 | 30 | 7 | 0.3 | |

| SS16003 | 35 | 8 | 0.3 | |

| SS6003 | 35 | 10 | 0.3 | |

| SS6203 | 40 | 12 | 0.6 | |

| SS6303 | 47 | 14 | 1 | |

| SS6403 | 62 | 17 | 1.1 | |

| SS6804 | 20 | 32 | 7 | 0.3 |

| SS6904 | 37 | 9 | 0.3 | |

| SS16004 | 42 | 8 | 0.3 | |

| SS6004 | 42 | 12 | 0.6 | |

| SS6204 | 47 | 14 | 1 | |

| SS6304 | 52 | 15 | 1.1 | |

| SS6404 | 72 | 19 | 1.1 | |

| SS6805 | 25 | 37 | 7 | 0.3 |

| SS6905 | 42 | 9 | 0.3 | |

| SS16005 | 47 | 8 | 0.3 | |

| SS6005 | 47 | 12 | 0.6 | |

| SS6205 | 52 | 15 | 1 | |

| SS6305 | 62 | 17 | 1.1 | |

| SS6405 | 80 | 21 | 1.5 | |

| SS6806 | 30 | 42 | 7 | 0.3 |

| SS6906 | 47 | 9 | 0.3 | |

| SS16006 | 55 | 9 | 0.3 | |

| SS6006 | 55 | 13 | 1 | |

| SS6206 | 62 | 16 | 1 | |

| SS6306 | 72 | 19 | 1.1 | |

| SS6406 | 90 | 23 | 1.5 | |

| SS6807 | 35 | 47 | 7 | 0.3 |

| SS6907 | 55 | 10 | 0.6 | |

| SS16007 | 62 | 9 | 0.3 | |

| SS6007 | 62 | 14 | 1 | |

| SS6207 | 72 | 17 | 1.1 | |

| SS6307 | 80 | 21 | 1.5 | |

| SS6407 | 100 | 25 | 1.5 | |

| SS6808 | 40 | 52 | 7 | 0.3 |

| SS6908 | 62 | 12 | 0.6 | |

| SS16008 | 68 | 9 | 0.3 | |

| SS6008 | 68 | 15 | 1 | |

| SS6208 | 80 | 18 | 1.1 | |

| SS6308 | 90 | 23 | 1.5 | |

| SS6408 | 110 | 27 | 2 | |

| SS6809 | 45 | 58 | 7 | 0.3 |

| SS6909 | 68 | 12 | 0.6 | |

| SS16009 | 75 | 10 | 0.6 | |

| SS6009 | 75 | 16 | 1 | |

| SS6209 | 85 | 19 | 1.1 | |

| SS6309 | 100 | 25 | 1.5 | |

| SS6409 | 120 | 29 | 2 | |

| SS6810 | 50 | 65 | 7 | 0.3 |

| SS6910 | 72 | 12 | 0.6 | |

| SS16010 | 80 | 10 | 0.6 | |

| SS6010 | 80 | 16 | 1 | |

| SS6210 | 90 | 20 | 1.1 | |

| SS6310 | 110 | 27 | 2 | |

| SS6410 | 130 | 31 | 2.1 | |

| SS6811 | 55 | 72 | 9 | 0.3 |

| SS6911 | 80 | 13 | 1 | |

| SS16011 | 90 | 11 | 0.6 | |

| SS6011 | 90 | 18 | 1.1 | |

| SS6211 | 100 | 21 | 1.5 | |

| SS6311 | 120 | 29 | 2 | |

| SS6411 | 140 | 33 | 2.1 | |

| SS6812 | 60 | 78 | 10 | 0.3 |

| SS6912 | 85 | 13 | 1 | |

| SS16012 | 95 | 11 | 0.6 | |

| SS6012 | 95 | 18 | 1.1 | |

| SS6212 | 110 | 22 | 1.5 | |

| SS6312 | 130 | 31 | 2.1 | |

| SS6412 | 150 | 35 | 2.1 | |

| SS6813 | 65 | 85 | 10 | 0.6 |

| SS6913 | 90 | 13 | 1 | |

| SS16013 | 100 | 11 | 0.6 | |

| SS6013 | 100 | 18 | 1.1 | |