Metric Double Row Tapered Roller Bearings

Metric Double Row Tapered Roller Bearings Introduction:

Metric double row tapered roller bearings can withstand heavy radial loads, axial loads in two directions and have a high degree of rigidity.

They are mainly used in gearboxes, lifting equipment, rolling mills and mining machinery, such as tunnel boring machines

Double Row Taper Roller Bearings Structure:

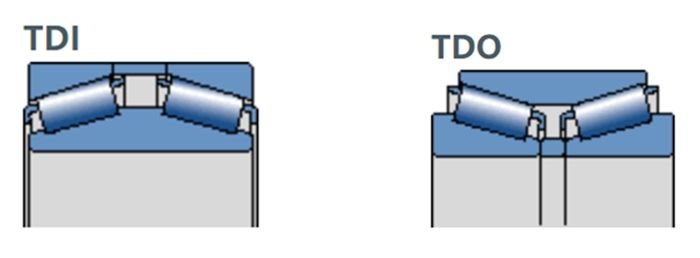

Metric double row taper roller bearings mainly have 2 structures- TDI and TDO.

For TDI structure:

Bearing has two outer rings and a double row inner ring with two roller and cage assemblies, usually with a spacer ring between the two outer rings.

Bearing rolling elements arranged face-to-face (load lines converge towards the axis of the bearing)

For TDO structure:

There is a double row outer ring and two inner rings with rolling element and cage inner ring assembly, usually there is a spacer ring between the two inner rings.

There are several rows of back-to-back rollers (the load line is separated to the axis of the bearing) to provide a more rigid bearing configuration and can withstand huge overturning moments

Advantages:

1. High carrying capacity

Double row tapered roller bearings can withstand heavy radial and axial loads. The axial load capacity of tapered roller bearings increases as the contact angle α increases. The size of the contact angle is usually between 10° and 30°. The size of the angle is related to the calculation coefficient e (data sheet). The larger the value of e, the larger the contact angle.

2. Bidirectional axial load

Tapered roller bearings locate the shaft in two directions and have a specific axial clearance or preload.

3. High stiffness

Double row tapered roller bearings provide a rigid bearing configuration.

4. Low friction

The optimized roller design on the rib and the surface finish of the rib can promote the formation of a lubricant film, thereby reducing friction. This also reduces the heat generated by friction and the wear of the ribs. In addition, the bearing can better maintain the preload and reduce the noise level during operation.

5. Improve operational reliability

The optimized surface treatment of the contact surface between the roller and the raceway is conducive to the formation of a hydrodynamic lubricant film.

Double Row Tapered Bearing Size Chart:

| d (mm) | D (mm) | T (mm) | C (mm) | Cr (KN) | Cor (KN) | New Model | Old Model | Mass (kg) | Grease Speed | Oil Speed |

| 150 | 210 | 86 | 70 | 419 | 887 | 352930 | 2097930E | 8.5 | 900 | 1300 |

| 250 | 138 | 112 | 858 | 1620 | 352130 | 2097730 | 26 | 850 | 1100 | |

| 270 | 164 | 130 | 1250 | 2250 | 352230 | 97530E | 38 | 800 | 1000 | |

| 270 | 172 | 138 | 1250 | 2250 | 352230X2 | 97530 | 38 | 800 | 1000 | |

| 160 | 240 | 115 | 90 | 641 | 1400 | 352032X2 | 2097132 | 14.9 | 850 | 1100 |

| 270 | 150 | 120 | 1050 | 2030 | 352132 | 2097732 | 32.5 | 800 | 1000 | |

| 290 | 178 | 144 | 1400 | 2730 | 352232 | 97532E | 49 | 700 | 900 | |

| 170 | 260 | 120 | 95 | 672 | 1460 | 352034X2 | 2097134 | 21 | 800 | 1000 |

| 180 | 280 | 134 | 108 | 952 | 1880 | 352036X2 | 2097136 | 29 | 670 | 850 |

| 280 | 142 | 110 | 952 | 1880 | 352036 | 2097136E | 28.5 | 800 | 1000 | |

| 300 | 164 | 134 | 1290 | 2540 | 352136 | 2097736 | 44 | 670 | 850 | |

| 320 | 192 | 152 | 1750 | 3350 | 352236 | 97536E | 62.5 | 600 | 750 | |

| 190 | 289.5 | 100 | 40 | 750 | 1500 | 372038 | – | 27 | 700 | 900 |

| 320 | 170 | 130 | 1440 | 2800 | 352138 | 2097738 | 51 | 670 | 850 | |

| 200 | 280 | 116 | 92 | 758 | 1423 | 352940X2/YA | 2097940EK | 14.8 | 700 | 900 |

| 280 | 105 | 80 | 650 | 2660 | 352940X2 | 2097940 | 18.5 | 700 | 900 | |

| 310 | 152 | 120 | 1180 | 2720 | 352040X2 | 2097140 | 41 | 670 | 850 | |

| 340 | 184 | 150 | 1680 | 3340 | 352140 | 2097740 | 64 | 670 | 850 | |

| 360 | 218 | 174 | 2310 | 4250 | 352240 | 97540E | 90.5 | 600 | 750 | |

| 220 | 300 | 110 | 88 | 660 | 1710 | 352944X2 | 2097944 | 21.2 | 670 | 850 |

| 340 | 165 | 130 | 1360 | 2790 | 352044X2 | 2097144 | 47.7 | 600 | 750 | |

| 370 | 195 | 150 | 1740 | 3450 | 352144 | 2097744 | 76.3 | 600 | 750 | |

| 230 | 355 | 145 | 110 | 1060 | 2040 | 350646D1 | 37746 | 43.6 | 600 | 750 |

| 240 | 320 | 116 | 92 | 820 | 1910 | 352948 | 2097948E | 22.3 | 600 | 750 |

| 320 | 110 | 90 | 820 | 1910 | 352948X2 | 2097948 | 23 | 600 | 750 | |

| 360 | 165 | 130 | 1370 | 3180 | 352048X2 | 2097148 | 52.8 | 530 | 670 | |

| 360 | 166 | 128 | 1370 | 3180 | 352048 | 2097148E | 55.6 | 530 | 670 | |

| 260 | 360 | 134 | 52 | 1150 | 2300 | 372952K | – | 43.5 | 530 | 670 |

| d (mm) | D (mm) | T (mm) | C (mm) | Cr (KN) | Cor (KN) | New Model | Old Model | Mass (kg) | Grease Speed | Oil Speed |

| 260 | 360 | 134 | 108 | 1263 | 2430 | 352952X2 | 2097952 | 36.8 | 530 | 670 |

| 400 | 150 | 110 | 1240 | 2330 | – | 37852 | 60.3 | 530 | 670 | |

| 400 | 186 | 146 | 1780 | 3830 | 352052X2 | 2097152 | 76.8 | 500 | 630 | |

| 400 | 190 | 146 | 1780 | 3830 | 352052 | 2097152E | 79.5 | 500 | 630 | |

| 430 | 180 | 130 | 2100 | 2800 | 350652D1 | 37752 | 87.9 | 500 | 630 | |

| 430 | 180 | 130 | 2237 | 3016 | 350652 | 97752 | 93.4 | 500 | 630 | |

| 440 | 225 | 180 | 2480 | 5050 | 352152 | 2097752 | 124 | 450 | 560 | |

| 280 | 380 | 134 | 108 | 1080 | 2810 | 352956X2 | 2097956 | 41.3 | 480 | 600 |

| 420 | 133 | 106 | 1270 | 1936 | 351056 | 97156 | 58.1 | 450 | 560 | |

| 420 | 186 | 146 | 1860 | 4000 | 352056X2 | 2097156 | 81.5 | 450 | 560 | |

| 300 | 420 | 160 | 128 | 1470 | 3530 | 352960X2 | 2097960 | 64 | 450 | 560 |

| 460 | 210 | 165 | 2200 | 4940 | 352060X2 | 2097160 | 118 | 430 | 530 | |

| 500 | 205 | 152 | 2200 | 4500 | 351160 | 1097760 | 144 | 400 | 500 | |

| 320 | 440 | 160 | 128 | 1410 | 3830 | 352964X2 | 2097964 | 67 | 430 | 530 |

| 480 | 210 | 84 | 2340 | 6130 | 372064X2 | – | 133 | 400 | 500 | |

| 480 | 210 | 160 | 1830 | 4390 | 352064X2 | 2097164 | 122 | 400 | 500 | |

| 340 | 460 | 160 | 128 | 1575 | 4050 | 352968X2 | 2097968 | 71 | 400 | 500 |

| 520 | 180 | 135 | 1904 | 4070 | 351068 | 97168 | 119 | 380 | 480 | |

| 580 | 242 | 170 | 2870 | 5970 | 351168 | 1097768 | 214 | 340 | 430 | |

| 350 | 590 | 200 | 140 | 2800 | 5500 | 350670 | 97770 | 212 | 320 | 400 |

| 360 | 480 | 160 | 128 | 1490 | 4270 | 352972X2 | 2097972 | 74.3 | 380 | 480 |

| 530 | 155 | 110 | 1690 | 3300 | 350672D1 | 37772 | 109 | 380 | 480 | |

| 530 | 155 | 110 | 1690 | 3300 | 350672 | 97772 | 107 | 380 | 480 | |

| 540 | 169 | 134 | 1980 | 3950 | 351072X2 | 97872 | 122 | 340 | 430 | |

| 540 | 185 | 140 | 2120 | 4910 | 351072 | 97172 | 127 | 360 | 450 | |

| 600 | 242 | 170 | 2950 | 6270 | 351172 | 1097772 | 235 | 320 | 400 | |

| 379 | 681.5 | 307 | 118 | 5600 | 11700 | 3706/379 | – | 512 | 300 | 380 |

Contact Us:

If you have any questions of Metric Double Row Tapered Roller Bearings, ple feel free to contact us!