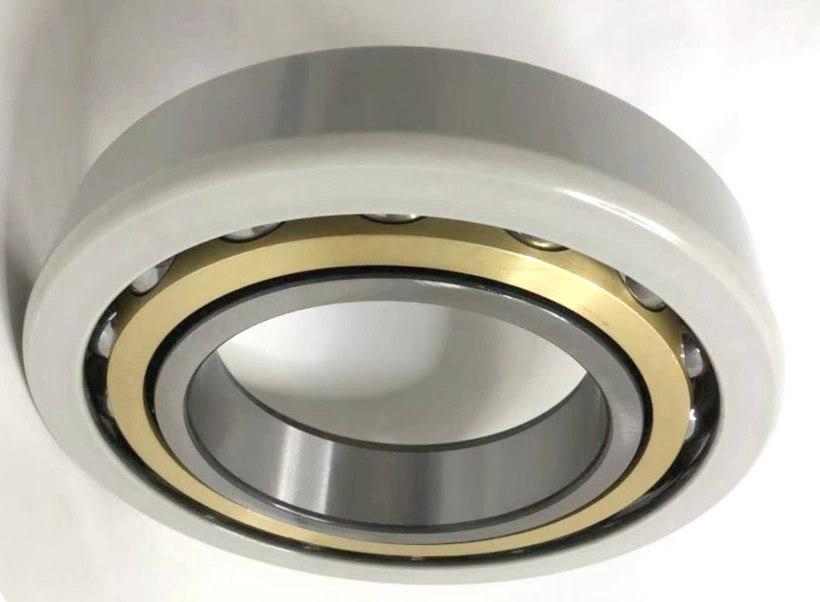

Ceramic Bearings Introduction

Ceramic Bearings Materials:

Ceramic bearings materials are as below,

Inner rings, outer rings and rolling material:

Zirconia (ZrO2), Silicon Nitride (Si3N4), Silicon Carbide (Sic)

Retainer material:

PTFE, Nylon 66, Polyetherimide, Zirconia, Silicon Nitride, Stainless Steel or Special Aviation Aluminum

Advantanges:

1. Ceramics are corrosion-resistant, so ceramic rolling bearings are suitable for working in harsh conditions full of corrosive media.

2. Because of the density of the ceramic rolling ball is lower than that of steel and the weight is much lighter, the centrifugal effect of the outer ring during rotation can be reduced by 40%. Therefore, ceramic bearings service life is greatly extended.

3. Ceramics are less affected by thermal expansion and contraction than steel, so when the bearing clearance is constant, ceramic bearing can work in an environment where the temperature difference changes more drastically.

4. Due to the elastic modulus of ceramics is higher than that of steel, it is not easy to deform when subjected to force, so it is beneficial to improve the working speed and achieve higher precision.

Classification of ceramic bearings according to applications:

(1) High-speed bearings:

It has the advantages of cold resistance, small force elasticity, high pressure resistance, poor thermal conductivity, light weight, and small friction coefficient.

Bearings an be used in high-speed spindles from 12000 rpm to 75000 rpm and other high-precision equipment

(2) High temperature bearing:

The material itself has a high temperature resistance of 1200 ° C and good self-lubrication. Operating temperature is between 100 °C and 800 °C without expansion due to temperature difference.

Therefore, bearings can be used in high-temperature equipment such as furnaces, plastics, and steel.

(3) Corrosion-resistant bearings:

The material itself is corrosion-resistant.

As a result, bearings can be used in strong acid, strong alkali, inorganic, organic salt, seawater and other fields, such as: electroplating equipment, electronic equipment, chemical machinery, shipbuilding, medical equipment, etc.

(4) Antimagnetic bearing:

Because ceramic is non-magnetic, it does not absorb dust, which can reduce the peeling of the bearing surface, thereby reducing bearing running noise.

So this kind bearings are suitable for demagnetization equipment, precision instruments and other fields.

(5) Insulated bearings:

Due to high resistivity, it can avoid arc damage to bearings.

So insulated bearings (eg. 6316-2Z/C3VL0241) are proper for various power equipments which require insulation.

(6) Vacuum bearing:

Due to the unique oil-free self-lubricating properties of ceramic materials, it can overcome the problem that ordinary bearings cannot achieve lubrication in an ultra-high vacuum environment.