How to Prevent Grease Washout in Bearings

The Role and Limitations of Bearing Seals

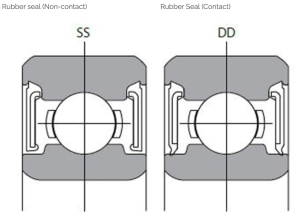

How to prevent grease washout in bearings? This is a common challenge for many bearing users. Bearing seals and shields serve as critical barriers to protect the lubricating grease inside the bearings. They effectively prevent external contaminants from entering while keeping the grease from leaking out. However, different types of seals offer varying levels of protection:

- Non-Contact Shields:

These shields do not make contact with the inner ring, which means they do not increase starting or running torque. However, their sealing performance is limited, making them less effective in preventing grease from being washed away. - Contact Seals:

Made of nitrile rubber, contact seals (eg: 2RS, RS) provide a tight seal by making direct contact with the bearing’s inner ring, offering superior protection against contaminants. However, they increase friction torque, which can affect the bearing’s operational efficiency. Additional protective measures may be required in such cases. - Intermediate Solution: Non-Contact Seals:

Non-contact seals strike a balance between shields and contact seals. Made of nitrile rubber, they do not touch the inner ring, ensuring no impact on torque or maximum speed. These seals offer better protection than metal shields and are suitable for most standard applications.

Professional Recommendations to Prevent Grease Washout

To achieve optimal protection against grease washout, consider the following strategies:

1. Choose the Right Lubricating Grease:

- High Water-Resistant Grease: Effectively resists water washout and maintains lubrication performance.

- Food-Grade Grease: Ideal for the food processing industry, capable of withstanding regular steam cleaning or chemical washing.

- PFPE Grease: Offers excellent chemical resistance, suitable for harsh environments.

2. Optimize the Sealing System:

- For high-speed, light-load applications, consider combining non-contact and contact seals.

- In heavy-load or high-contamination environments, use double-lip contact seals for enhanced protection.

3. Install Protective Devices:

- Add external protective covers around the bearing to reduce direct impact.

- Design drainage channels to prevent water accumulation and continuous exposure to the bearing.

4. Perform Regular Maintenance and Inspections:

- Check the condition of seals regularly for signs of wear.

- Monitor the state of the grease and replenish or replace it as needed.

By implementing these methods, the risk of grease washout can be significantly reduced, extending the lifespan of the bearings and ensuring stable equipment operation.

Contact Us:

If you have any questions about How to prevent grease washout in bearings, please don’t hesitate to contact us.